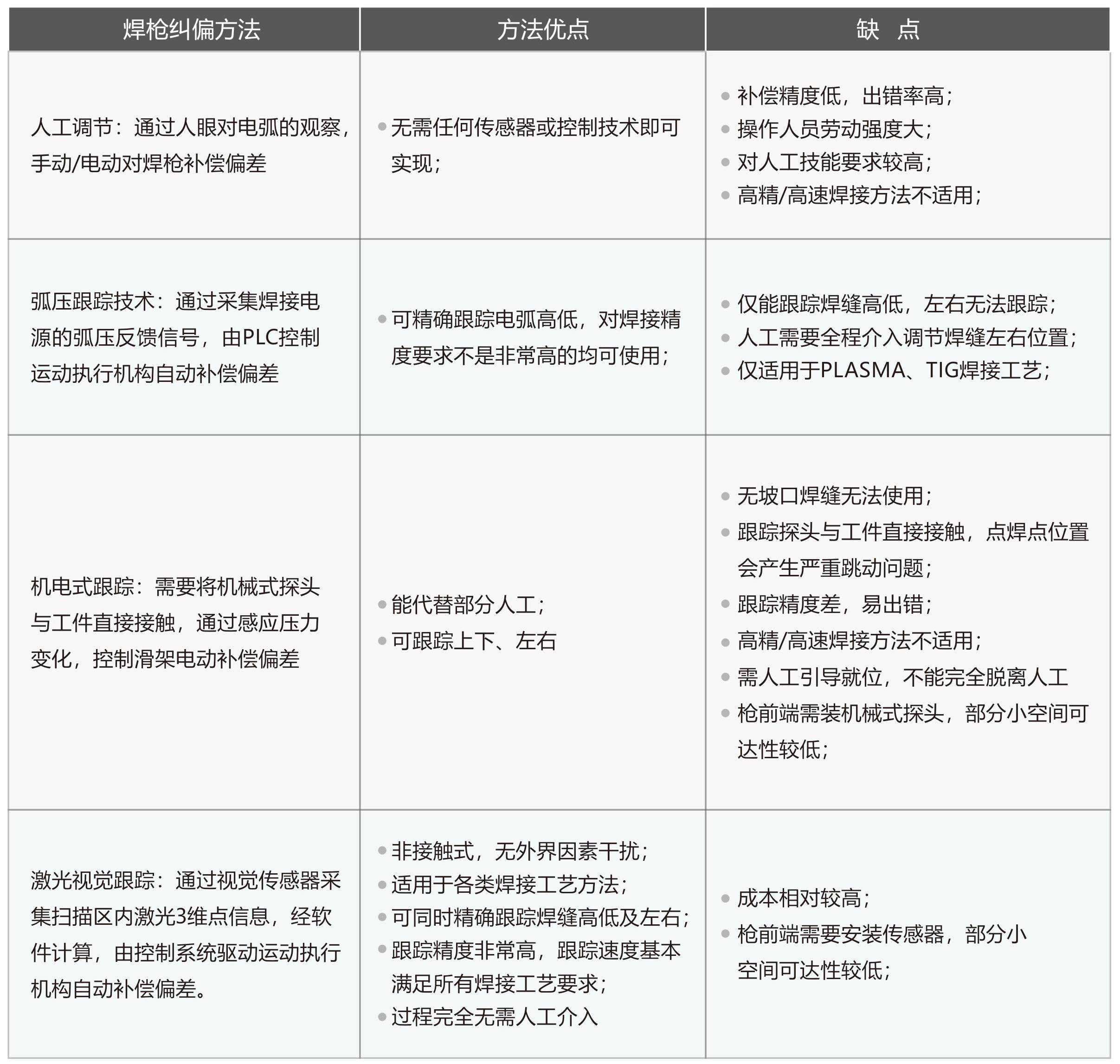

It is suitable for butt joint, lap joint, socket

joint, fillet joint and other forms of straight,

circular, spiral and other irregular welds;

It is suitable for TIG, MIG / MAG, saw, paw,

LBW and other multiple welding methods;

The modular design can be matched with the

welding machine controlled by the

mainstream brand PLC, which is convenient

for the transformation of old equipment of

various brands

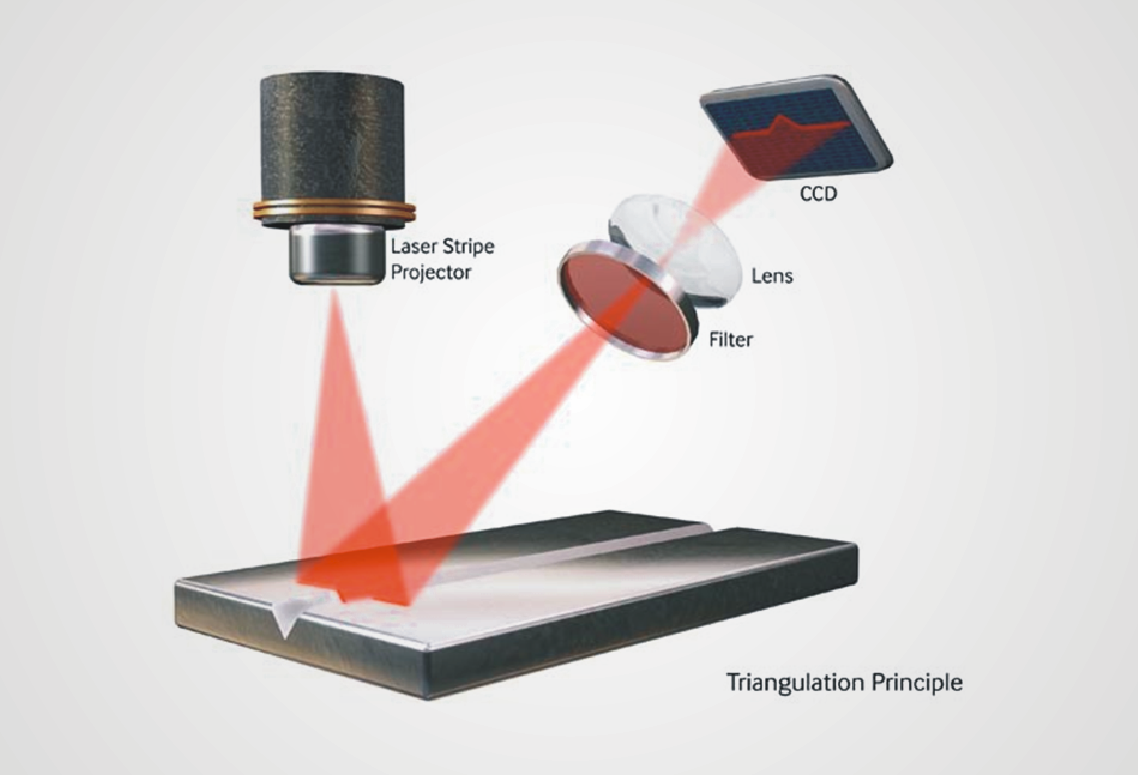

Integrated filter processing technology of

software and hardware, effectively shield arc

light, splash and other interferences, and

accurate weld identification

The hand eye calibration is simple and

convenient, and its relative position

coordinates can be changed at any time,

which is automatically called during software

operation

Customized special data communication

protocol, easy to integrate with any brand

of welding controller

Intelligent identification and fuzzy optimal

control technology of trajectory can ensure

the welding position and abnormal position

of welding seam, and the welding gun can

still move smoothly and accurately;

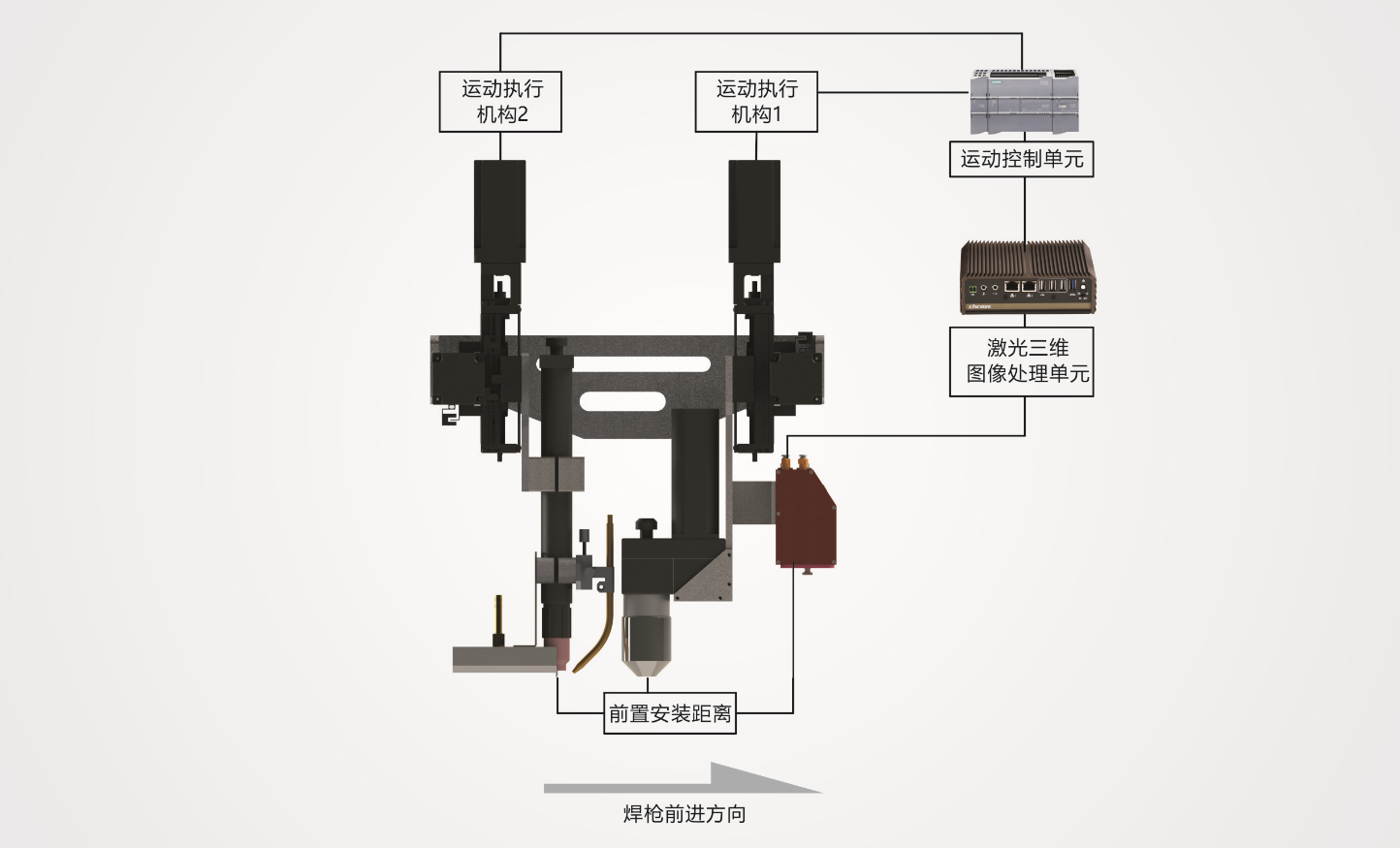

By binding the sensor with the actuator, it can

adapt to the detection and tracking of the

welds with a wide range of changes in the

position of the welds;

Intelligent weld identification and initial

industry identification can greatly improve

the degree of automation, without manual

participation, and improve the utilization rate

of manpower and the stability of product

quality

For complex working conditions or special

applications, customized services can be

provided.

Technology extension application: nozzle

identification, gap measurement, product

dimension measurement, product defect

detection, cylinder roundness measurement,

AGV navigation and precise positioning, roll

displacement control system of plate rolling

machine, etc